Our Products

Filter Press

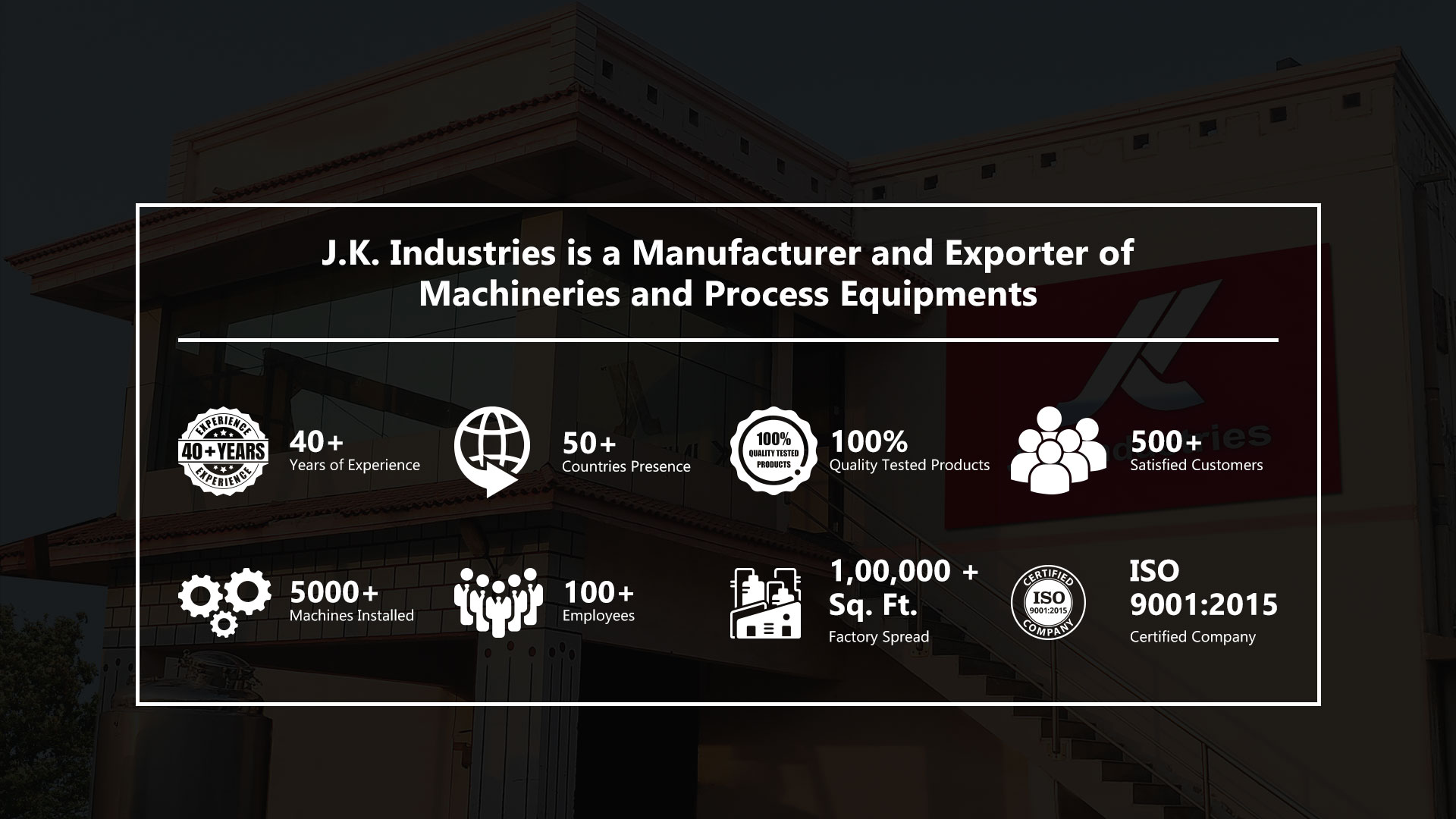

The JK Industries range of Filter Presses are used for wide range of applications by several industries like Pharma, bulk drugs, distilleries, beverages & other industries. There are more than 5,000 units supplied since last 35 years.

READ MORE

Ribbon Blenders

The RIBBON BLENDER is an efficient and versatile blending machine for mixing of dry granules & powders homogeneously. Approximate two third of the volume of the container of Ribbon Blender is filled to ensure proper mixing.

READ MORE